Add an extra thrill to albee fishing by hooking a speedster to your creations.

I am a self-confessed Albee fan. After I achieved my first albee in 2014, I was screwed. The hissing sound of the line cutting through the water as the fish run screaming around the bow is seared into my memory. Albie season is very short, only eight weeks in my home state of Connecticut, but we spend the rest of it counting down the days until the speedsters return.

In the middle of a recent winter, I decided to try making my own albee jig. It quickly became clear that the holographic finish on commercially available cans would be difficult to recreate in my basement, but the idea of catching albies with a lure of my own making was too tempting and there was no turning back. was.

I've always enjoyed making my own fishing gear. It's a hobby that combines some of my favorite things: fishing, tinkering, and saving money. As a child, I remember pouring sinkers in the driveway with my father and brother. In recent years, I've become obsessed with homespun blackfish jigs, bucktails, pouring and powder coating jig heads. It is simple compared to the flashy finish of commercially available albee jigs. However, after some research I was pleased to discover that applying a holographic foil finish to a jig is actually quite possible in your home workshop.

This technique is called foil stamping and is often used in stationery stores to achieve a luxurious metallic print. The foiling technique has been adopted by crafty anglers and is perfect for adding a factory-grade finish to home poured jigs. I believe the best way to get good at something is to be bad at it first. This was definitely my experience with Albie Jig. In the end, there were no mistakes and we were able to achieve great results. By sharing these lessons, we hope to help others take up a new and satisfying hobby that will help prevent off-season Albee fever.

the mold

The first step on the assembly line is to manufacture or source a bare lead jig body with the appropriate baitfish profile. For albies, jigs are relatively small, weighing between 3/4 ounce and 1-1/2 ounce. If you're not interested in pouring lead, there are a variety of unfinished lead jigs available for purchase online.

To make your own jig, you will need a mold. Do-it Molds is the largest manufacturer of molds for DIY tackle makers and makes two of his styles that are extremely useful for making albee jigs. The Do-it Minnow Spoon mold features an elongated, narrow baitfish profile that can be used to imitate baits such as silverside and anchovies. Their shad spoons offer a deeper body profile, creating jigs that perfectly mimic peanut bunkers. Each mold features three cavities: 3/4 oz, 1 oz, and 1-1/2 oz.

What I like about these molds is that Do-it also makes pre-formed through-wire inserts designed for these jigs. The mold holds the wire while pouring, and the lead encapsulates the wire, creating the finished jig. Please follow my advice and buy the wire. Trying to bend it yourself is a nightmare.

pour lead

For albee jigs, I prefer to use a “hard lead.” It is actually a mixture of lead and small amounts of other metals such as tin and antimony. Pure lead is very soft, so a thin-bodied Albee jig will easily lose its shape during a fight with a fish or after hitting a rock. Preheating the mold before pouring helps produce better, more stable castings. Hot molding allows the molten lead more time to completely fill the cavity before cooling and solidifying. Preheating is especially important when using hard reeds that tend to harden quickly.

When pouring small albee jigs, use a bottom pourry pot with a 10-pound capacity. In this pot, when a lever is lifted, molten lead flows out of a small spout at the bottom of the crucible. This is much easier, cleaner, and more accurate than pouring by hand with a ladle. Once the jig has cooled enough to maintain its shape, it can be removed from the mold. Each jig has sprues, which are “knobs” that remain by the spout, and these can be removed using diagonal pliers.

Finally, powder coat the jig with white powder paint before applying the foil. This will give you a smooth finish with no imperfections. If you've never used a powder painted jig before, there are hundreds of tutorials on YouTube.

foil time

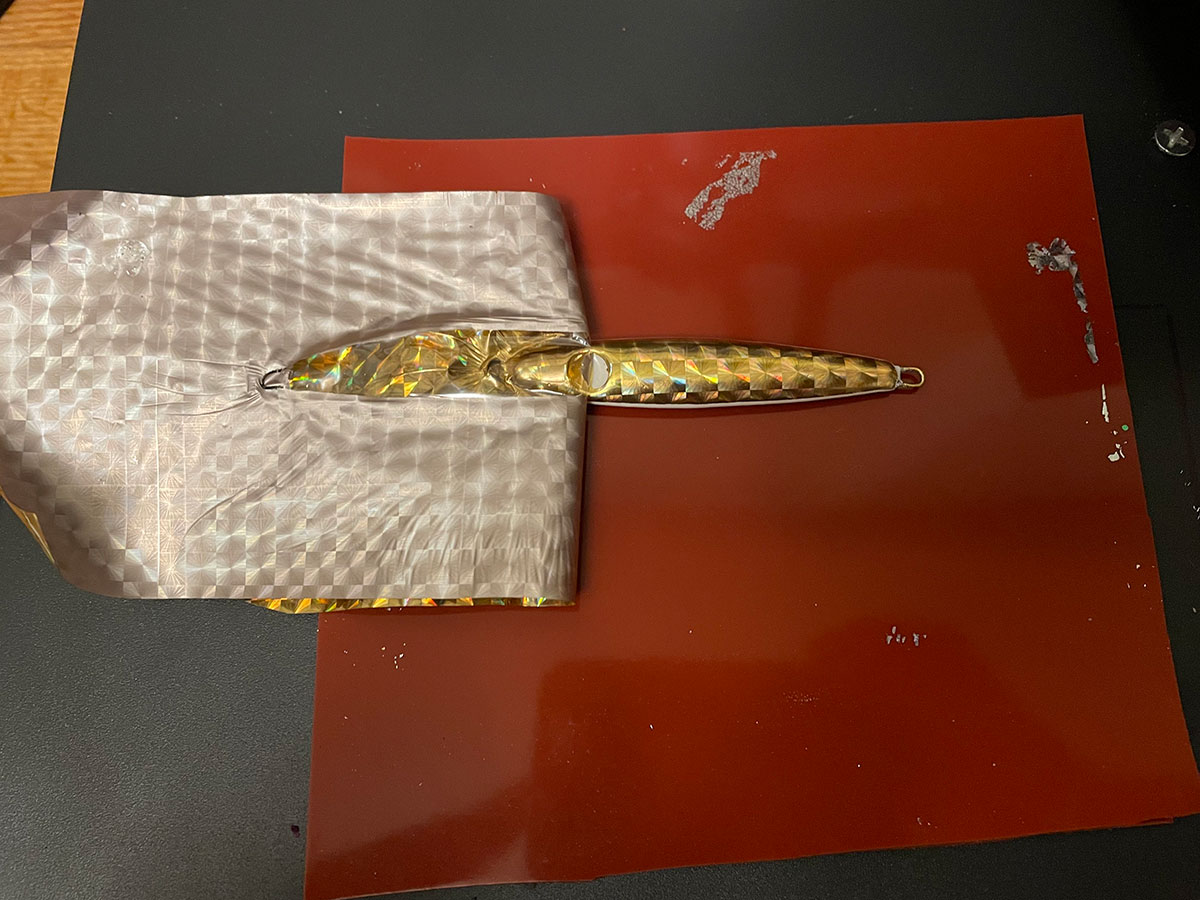

Applying hot stamping foil is a step in the process that can be fun to work with, but it also requires learning new skills. Hot-stamped foil comes in 30-foot rolls of 3-inch wide material, and the holographic foil is matched with a wrinkled plastic backing. Heat is used to fuse the foil to the jig, no glue is used. A smooth silicone pad heated in a Panini or T-shirt press provides the heat and conforms to the shape of the jig as you press the foil onto the reed. The pads I'm using were ordered on eBay from Varna Fishing, a small Bulgarian company. To complete the transfer, the foil must be pressed against the jig with even pressure. I much prefer T-shirt presses. This is because it applies even pressure to the pad and does not require physical effort to maintain pressure like a panini press.

The first step is to place the silicone pad on the heating element of the press and preheat it to 300-325 degrees. Measure by inserting a meat thermometer into the side of the pad. Next, place the powder-coated jig on a smooth, soft, heat-resistant mat and place a strip of foil over the jig. Next, place the foil, jig, and mat on the bottom plate of the press. Gently place the hot silicone pad over the foil and jig, close the press and press the silicone pad onto the foil and jig. Maintain even pressure for 15-30 seconds, then open the press and gently remove the pad. The foil appears to be vacuum sealed around the leads. Lift up the corner of the foil strip and gently peel it away from the jig. This will cause the backing material to peel away and reveal your beautiful foiled result. Flip the jig over and repeat the process on the other side.

Although the foil finish is secured to the jig, please note that it is delicate and can scratch if not protected. Before painting the jig, apply a thin coat of Rustoleum clear coat. I learned the hard way that if you omit this intermediate clear coat, the finish will be less durable. If the jig is not sealed before painting, the outer clear coat will inevitably chip and the foil may peel away from the jig.

the devil is in the details

When the paint hits the foil and the final product comes into focus, it takes the job up a notch. Use an airbrush to apply smooth color accents over the foil. Most of my jigs feature a simple band of color along the back. However, with a little practice, you can add details using scale patterns and accent colors. Mesh bags for onions and garlic create wonderful scale patterns. Painting small lures with an airbrush can be frustrating. We recommend practicing with paper or old, worn-out lures first to get a feel for it.

We also recommend learning how to disassemble and clean your airbrush. Even high-quality brushes can get clogged if you don't clean them regularly. I've been very happy with his Createx paints and this reducer really helps me create fine lines and gives me an even coat. We use flesh tones, white, olive, pink, chartreuse, and silver to cover a variety of baitfish patterns. Once the painting is complete, carefully secure the stick-on eyes. However, if you try to change the position of the eye, the paint will often peel off from the jig and ruin the painting, so be sure to do it accurately.

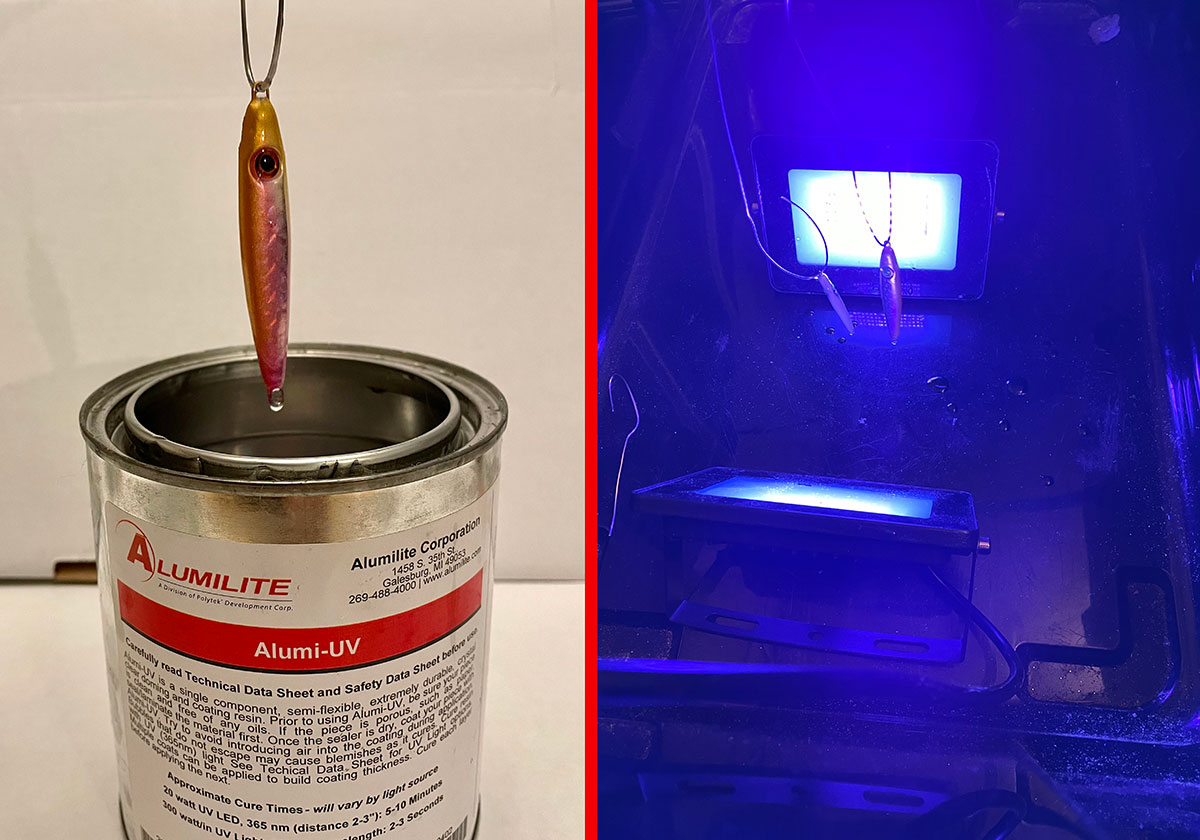

Next, add a coat of protective clear finish. There are many options, but I've had great luck with Alumilite UV resin, which cures in about 30 minutes when exposed to UV light. To apply, hook the painted jig onto a bent wire and lower it into the resin can until it is completely submerged. Then, lift the jig and drip excess resin into the can until a thin, even layer of resin remains. Next, he hangs the jig between two UV lamps for 30 minutes, or until the finish no longer feels tacky. Place the UV lamp inside a cardboard box and hang the jig from a dowel secured above the light. The clear coat really makes everything pop. It's really satisfying to look at the end result and remember a piece of bare lead transformed into a jig that can fool the discerning Albie.

This fall I was able to test out my jig. I fished it like any other albie jig, with long casts, fast retrieves, and praying that the fish would want to eat it. They had a good cast, great action, and enough charm to fool a few albies. This was a very satisfying experience and I hope other albeenuts will share it.